Our Advantage

Furniture Finish

Once we select premium quality lumber, we meticulously match and hand-sand each-piece. The material then undergoes a 14-step finishing process that ends with the application of a catalyzed conversion topcoat to prevent scratching and scuffing. During every stage of the manufacturing process, our products undergo a thorough evaluation to guarantee that the end product is immaculate.

Construction

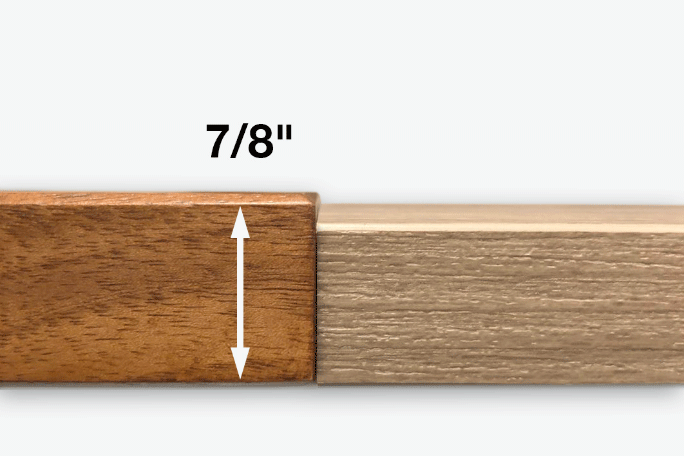

Every cabinet we produce is certified Carb 2 compliant and built to the highest specification possible to ensure durability and longevity. Our standard all-wood box construction features premium 9-ply plywood for structural integrity, squareness and precision. As an added bonus, almost every part of our cabinet is edge-banded and laminated, including the tops, sides and bottoms to reduce warping and the harmful effects of water.

Storage

Our full access, frameless construction maximizes storage and accessibility in the kitchen. Because our cabinetry does not have a frame that protrudes into the cabinet opening, the interior is readily accessible which makes storing large platers, cookware and plates easy. While most wall cabinets are manufactured 12” deep, our wall cabinets are 13” deep as a standard to provide even more storage for larger household items.

Ever-Lock Shelf

Our shelves are crafted from solid 3/4” plywood which is edge-banded on all four sides and then finished with a sophisticated European style front edge. In addition to being aesthetically unique, each shelf we manufacture is designed with stability in mind and features our ever-lock system. This system utilizes stainless steel shelf clips that lock into pre-drilled holes that are bored into the bottom of the shelf to prevent movement and ensure the sturdiness of the shelf and overall structure of the cabinet.

Drawer Box

Our solid maple, 3/4” drawer box features dovetail joinery and a 3/8” bottom for added support and load resistance. Every drawer box we manufacture features soft-close, full-extension under-mount hardware to maximize storage space and make operation a breeze.

Leaks, spills and minor floods are common in the kitchen which is why every St. Martin cabinet sits on leveling feet to prevent it from wicking up minor amounts of water. This will ultimately increase the longevity of your kitchen and also prevent musty smells that occur when wood soaks up moisture.

Cabinet Features

14-Step Furniture Finish